News

-

What are the algorithmic advantages of the high-end FVM-CNC image measuring instrument in workpiece edge recognition and contour fitting?

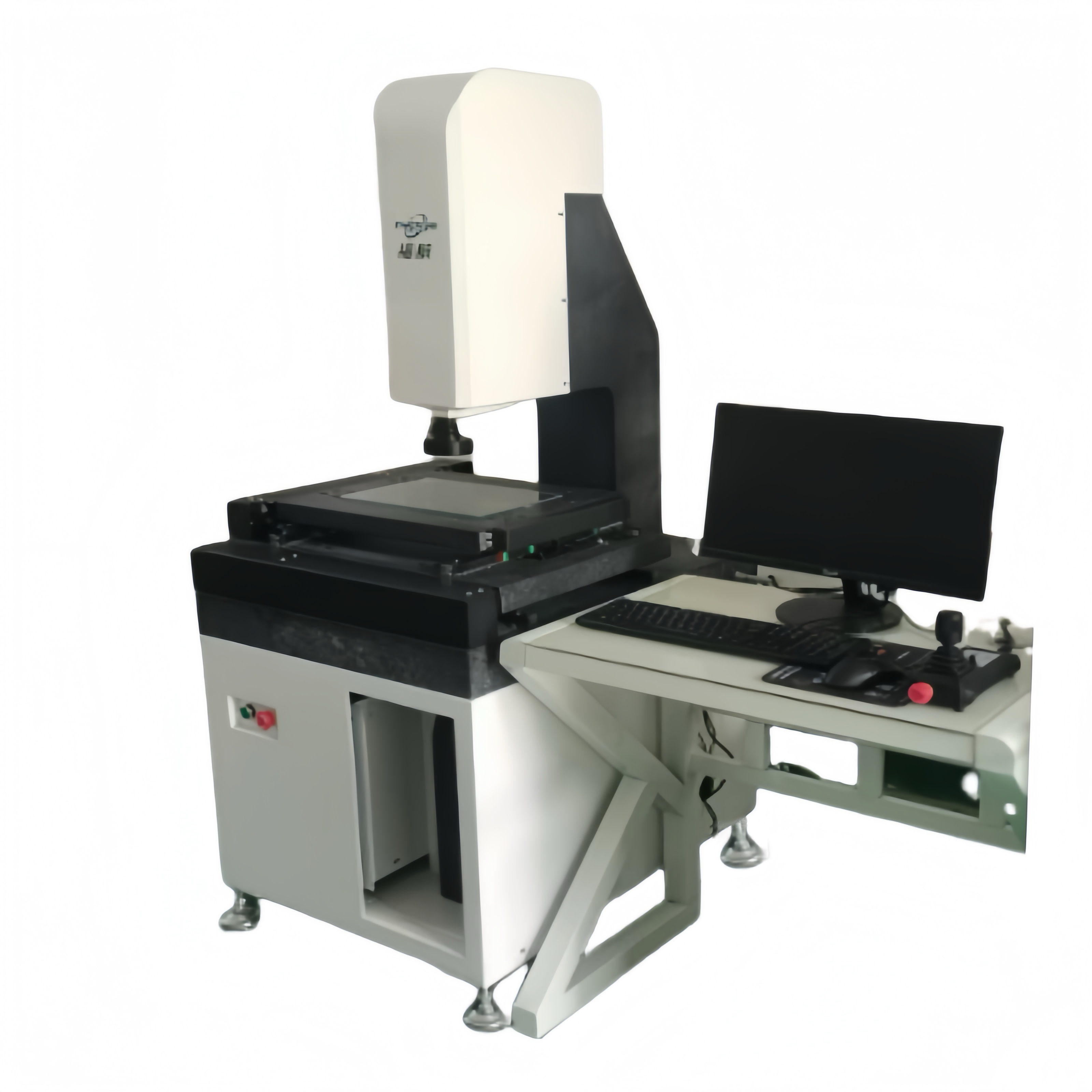

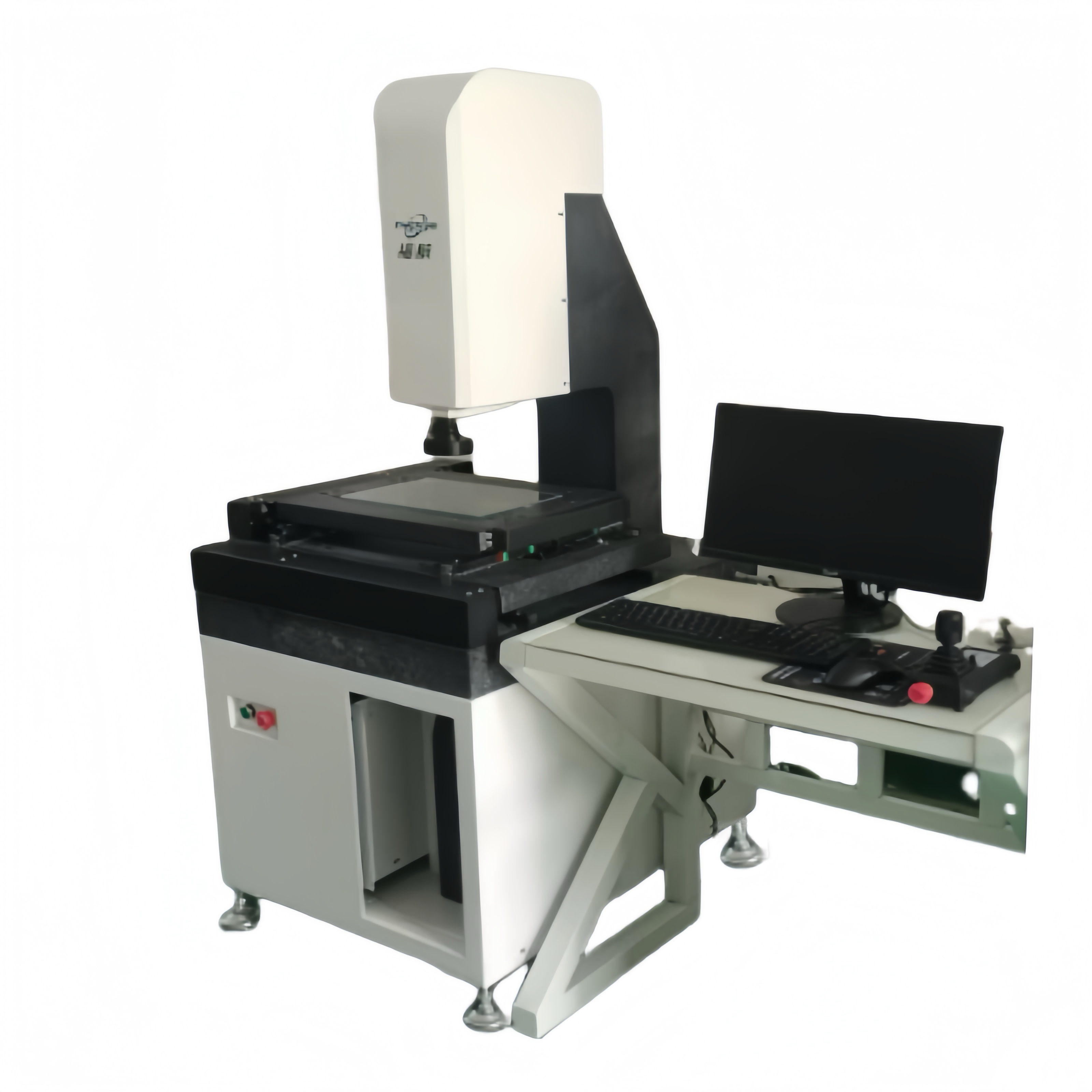

The high-end FVM-CNC image measuring instrument, with its compact structure and highly stable optical platform, combined with its independently developed intelligent measurement software, demonstrates significant algorithmic advantages in workpiece edge r

Learn More2026-02-17 -

How can the image stitching function of the FVM-B manual image measuring instrument achieve seamless measurement of large workpieces?

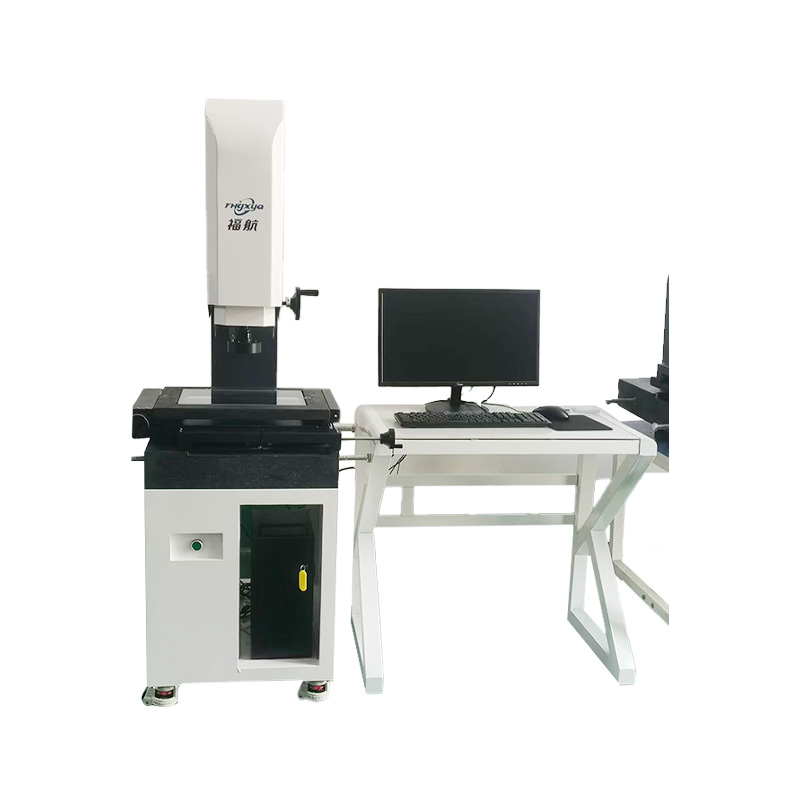

Its light source system adopts a programmable LED cold light source, which supports multi-mode switching of surface light, contour light and coaxial light, and can optimize imaging contrast for workpieces of different materials.

Learn More2026-02-03 -

How can Gantry High-End FVM-CNC Imager improve detection comprehensiveness through multispectral fusion?

Gantry High-End FVM-CNC Imager achieves a leap from single-spectrum detection to multi-dimensional feature analysis through multispectral fusion technology.

Learn More2026-01-21 -

How can the frame rate stability of the basic FVM-CNC imager be guaranteed during high-speed dynamic measurements?

As a device designed specifically for high-precision dynamic measurement, the frame rate stability of the basic fvm-cnc imager is a core indicator for ensuring the reliability of measurement data.

Learn More2026-01-07 -

What factors affect the repeatability of the FVM-B manual image measuring instrument?

The FVM-B's optical system includes key parameters such as lens distortion, light source stability, and image sharpness.

Learn More2025-12-23 -

Does the Basic FVM-CNC Imager support autofocus or edge detection assistance?

In the field of precision measurement, image clarity and the accuracy of edge positioning directly determine the reliability of 2D and even 2.5D dimensional data.

Learn More2025-12-09